Quality Process & Manufacturing

We take great satisfaction in using the most up-to-date machines like the Atom Italian Clicking Machine and technology in our workshop, which allows us to produce the highest quality leather products possible.

Our products are made with absolute care, using the best quality leather available for our buyer’s leather products’ requirements. At our workshop, we also focus on devising an extensive quality-control process that ensures precision.

Our workshop employs a team of skilled artisans, who are considered to be masters in the Indian leather industry in their respective fields. The experience, judgment, and skills of our craftsmen help us meet quality standards in leather production.

Process

Providing premium quality leather good since 1983

Material Room

All materials procured are stored in

an organised manner under camera security. The material room is managed routinely to keep it hygienic and material health friendly. All procured materials, once purchased, are put under a systemised inventory for periodic maintenance.

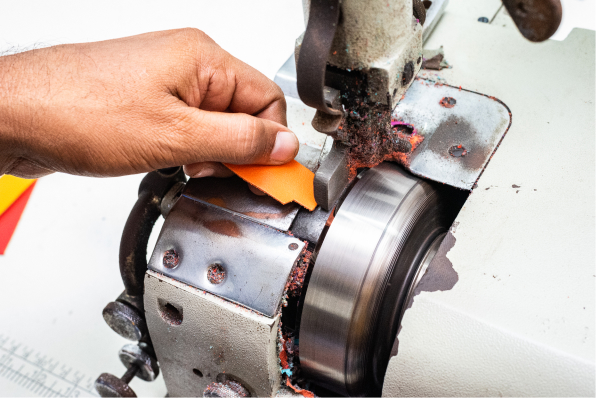

Leather Cutting

For accurate, faster and efficient leather cutting we use latest Atom Italian Clicking machines. When it comes to precision leather cutting with the least amount of waste possible, these machines are excellent. These machines are more expedient as well as more efficient. Simultaneously, our skilled labour ensures minimum wastage.

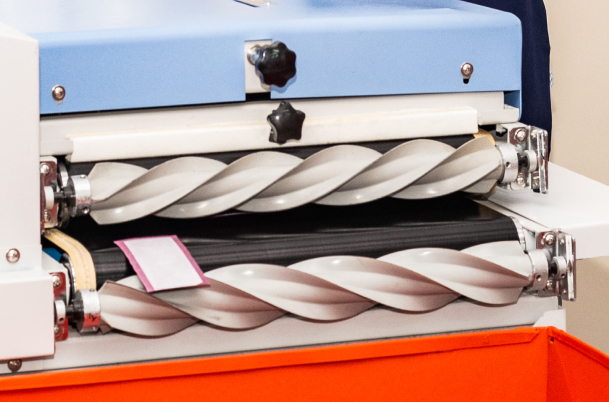

Splitting & Skiving

With the use of latest machinery and highly skilled labour, we ensure high precision

skiving and splitting of leather which is important for high quality finish of product.

Sampling

As per buyers specification and design needs, our experienced team with the use of CAD/CAM facility creates multiple prototypes and samples for client approval. Our entire procedure is geared at providing the buyers with a smooth and flawless buying experience. We work in accordance with the requirements of the buyer, delivering swift samples for rapid approval.

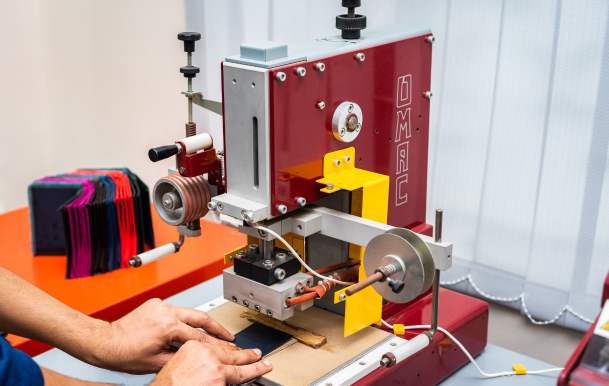

Plating & Roto Press

For a refined gloss effect, smoothness and the soothing feel of leather as well as hard pasting, we use MAC SRL Italian Plating and Rotto Press machines.This step assures a clean finish, ensures smoothness of the leather, and a shining surface, which are all indicators of the product’s quality.

Hydraulic Embossing

Machine

When it comes to leather manufacturing, embossing is one of the most important operations. Pressure and heat are balanced in such a way that they work together flawlessly to expedite the process. We use high quality heat and pressure embossing machines for the ultimate emboss finish as per design requirements.

Hot-lining

For accurate and easily visible hotline on products, we use state-of-the-art automatic hot-lining machines. Our machinery is capable of producing and meeting the needs of our customers who require customised solutions.

Assembling – Glueing & Pasting

This is the first step in the assembly process, during which different departments undertake glue and pasting activities on various elements of the product prior to moving on to the next step.

Assembling – Stitching

Under this step, with the assistance of high-quality stitching equipment and a highly competent workforce, all parts of the product are stitched together using high-quality, industry-standard threads during this process.

Quality Check

Despite the fact that we have quality control at every step, this is the most critical step that assures we remain the preferred manufacturer for many European clients. We do a thorough quality check on each product in accordance with the specifications provided by the client.

Packaging

Finally, we package each product according to the specifications provided by the client. We make certain that the products preserve their freshness and that they are resistant to any damage that may occur during shipping.